Automated goods receipt samples

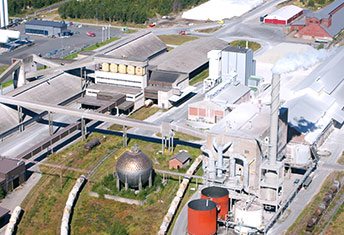

Automation processes are becoming increasingly important in heavily frequented goods receiving points. In industry 4.0, industrial robots automatically take samples from trucks or trains and transfer them to Sumetzberger's AutoLoad stations and in just a few moments, the samples reach the laboratory where they are automatically unloaded.

The system forms a closed circuit in which the carriers do not leave the system.

Cost savings through controlled workflows

Every transport is monitored in real time, recorded electronically and can be evaluated at any time. Sumetzberger pneumatic tube software can be integrated into any existing software program and ERP system. Evaluations regarding exact sampling time, transmission frequency and transmission duration can thus be combined with analysis times in the laboratory, truck downtimes etc.

Cost savings through reduction of personnel costs

Errands involving personnel have a cost implication that can be difficult to record and analyse, but with Automated pneumatic tube systems, incoming samples are directly transported to the laboratory, without any delay, detour, completion of work or distraction. At the same time every transport is recorded and documented.

Reduced downtimes of trucks and trains

Due to the automated sampling, downtimes of trucks and trains can be greatly reduced.

Tays HTJ Niko Laurila (1).jpg)