Pneumatic Tube Systems for Industry

Pneumatic Tube Systems for Industry

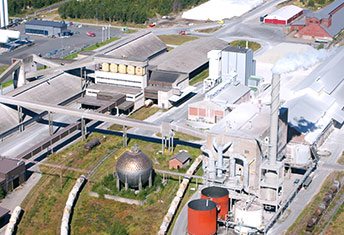

Sumetzberger's pneumatic tube system solutions for industry, are important parts of the optimised and efficient quality control for incoming goods inspection and production samples control worldwide. Maintenance and repair work is reduced by the delivery of small parts. Documents, which are required in their original form, are transmitted safely and quickly to relevant personnel.

Pneumatic tube systems deliver to any building on a factory site, even if they are separated by road or rail. Not only between buildings, but also across several floors, well planned pneumatic tube systems lead to a strong cost reduction, irrespective of distance. Loading and unloading of the carrier can be carried out manually or automatically and each transport is monitored and logged in real time. Everything that can fit into a Sumetzberger carrier can be transported: cold or hot steel samples, hazardous goods, oils, liquids, powders, various small components, tools or additives and much more.

Tays HTJ Niko Laurila (1).jpg)